Kanban Just-In-Time (JIT) stock managment systems...

The kanban Just-In-Time (JIT) stock management system was originally created by a chief production engineer at a well known Japanese multinational company. His final kanban solution made it easy for the company to manage their inventory and receive stock just in time, while also improving work processes.

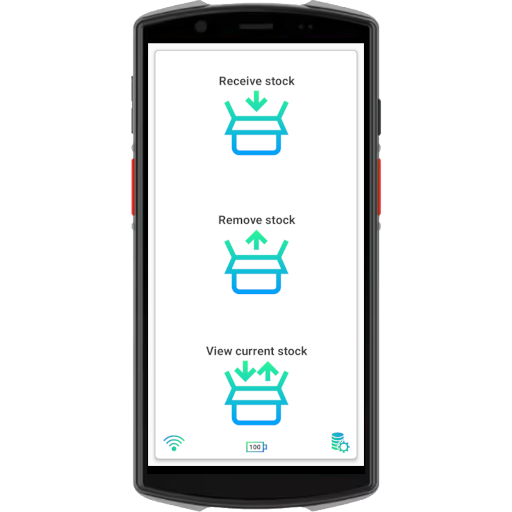

We create custom kanban stock control management systems specifically designed to help your small to medium sized business thrive. We develop both the Windows desktop software and also the Android 1D/2D/QR barcode scanner application to perfectly suit your business requirements. The aforementioned solutions are seamlessly integrated together via either MSSQL or MySQL database storage engines, creating the perfect match.

The purpose of the kanban card stock control system is to visualise minimal stock levels and to know when to replenish items, with reordering accomplished automatically when the QR code is scanned on the kanban card. For this reason, the kanban card system brings greater visibility and transparency to stock control.

We develop two types of bespoke Just-In-Time (JIT) stock control systems. Our first solution is 100% fully automated and relies on automatically monitoring stock levels via received purchase orders and generated invoices or delivery notes. Optionally, this solution can also utilise barcoding. The second solution uses stock control kanban cards in conjunction with barcode scanners to automatically generate purchase orders on your system. Both solutions effectively monitor your stock item levels.

Our purchase order and invoice solutions provide visual warnings of low stock while creating documents or viewing stock items. The kanban card system automatically generates new purchase orders when a kanban reorder card is scanned, ensuring that your business never runs out of stock.

A well integrated stock control kanban card system need not be expensive or complicated to set up and use. Working in conjunction with yourselves, we can develop the perfect automated Just-In-Time (JIT) kanban system at a reasonable price within your budget.

- Limits the build up of excess stock

- Customer satisfaction for deliveries being on time

- Easily link the warehouse to the purchase department

- Limit processes to eliminate bottlenecks

- Improved stock level calibration means you should never run out of stock

- Enables a more efficient workflow

- Uses one or more visual cues to automatically generate purchase orders

- Helps your business to run more smoothly and effectively

- A well integrated kanban card system can help your business cash flow, warehousing and workers productivity

- Kanban cards can be colour coded in order of priority (optional)

- Processes are clearly defined and simple to follow

Being able to rely on a system that works for you is essential in the day-to-day running of any business, including yours. Having reliable processes ingrained within your business starts with great software and hardware integration.

The key to a successful stock control kanban card solution is visual representation, which automatically triggers the reorder stock item process to replenish your stock. When a kanban card is reached, an employee scans the QR code on the Kanban card then continues their work. The software will automatically generate a new purchase order for the item of stock that needs reordering.

Using stock control kanban cards for Just-In-Time (JIT) stock management is not a new concept. Unlike many other stock control kanban card systems, our solutions are specifically developed with vertical integration in mind for stability, expansion and ease of use. Our bespoke software solutions use either MSSQL or MySQL database storage engines to seamlessly work with our Android powered 1D/2D barcode scanners. This ensures that no compatibility issues occur as all development is performed in-house.

Our stock control kanban card solutions are designed for efficiency, reducing and minimising the amount of Work-In-Progress (WIP) for your employees. This ensures that future dependencies start earlier and employees are not inefficiently waiting on others before starting their own tasks, thereby helping to manage workflow more efficiently.